Parallel Testing Using Automated Waveform Technology

(Patents and Patents Pending)

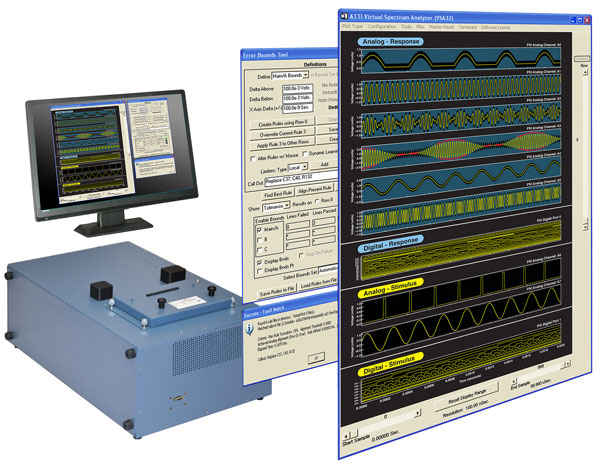

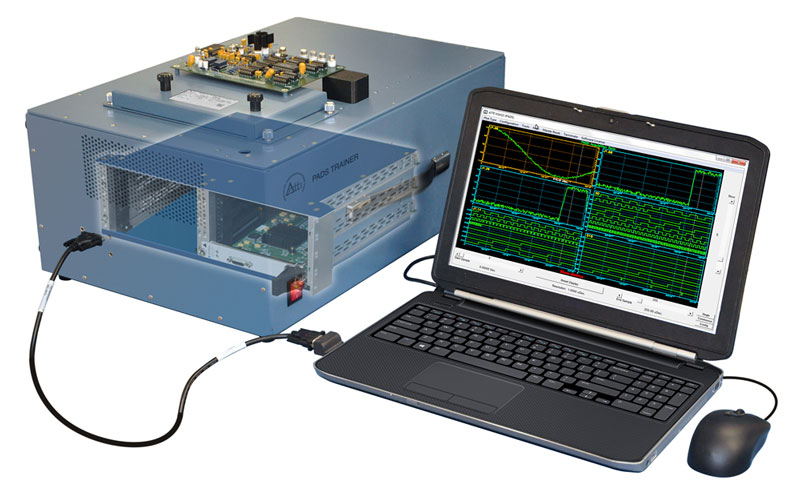

Parallel Automated Development System (PADS)

ATTI's parallel test system is the most efficient functional test system available.

A smaller, faster test system that:

- Reduces test program set (TPS) development time

- Increases Test Quality/Thoroughness/Fault Accuracy

- Reduces Test/Repair Times

- Provides a significant Reduction in ATE Size/Footprint

- Reduces TPS development time/cost

- Reduces station and ITA footprint

- Provides a two-fold or more increase in production throughput

- Features automated fault dictionary generation

- Increases the probability of intermittent fault detection

- Features Automated Code Generation (ACG) for macro execution and export

- Features new hardware architecture that eliminates switching subsystems

- Features new software architecture that streamlines development and test execution

- Reduces ITA complexity, size, and cost

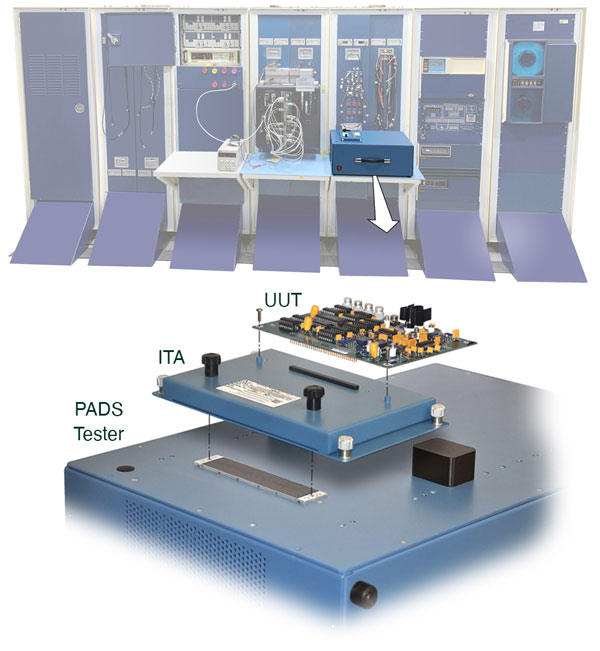

The ATTI Parallel Automated Development System (PADS) is a revolutionary new tester ideally suited for testing mixed signal units/devices under test (UUTs/DUTs). PADS can deliver significant benefits at reduced costs compared to common general-purpose testers. At the heart of the tester are its simultaneously available mixed signal stimulus and acquisition assets. The parallel analog system is typically configured with sixty-four (64) channels, the parallel digital system with one hundred twenty-eight (128) channels and the parallel power system with four programmable power channels. The PADS tester combines an intelligent mix of proprietary technologies in a small affordable test system.

The PADS toolset is a Graphic User Interface (GUI) based development system, which requires no coding, drawing or connecting by the user. The tight integration of the software is ground breaking and frees the TPS developer to direct their efforts toward test integration.

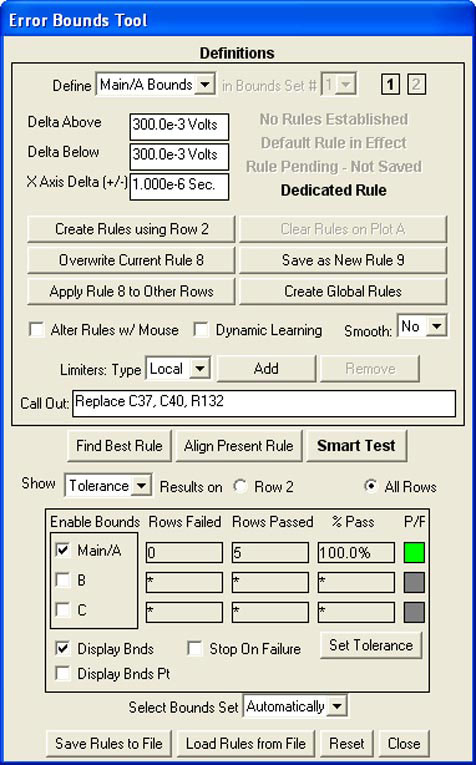

The PADS approach makes expensive and time-consuming diagnostic routines and manual probing a thing of the past. ATTI's combined technologies enable component fault identification through our patented waveform analytics, signal intelligence analysis and model automation.

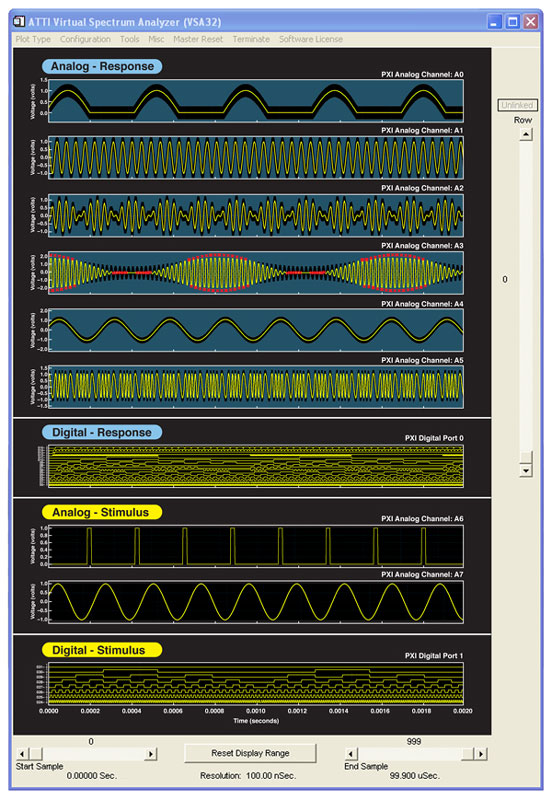

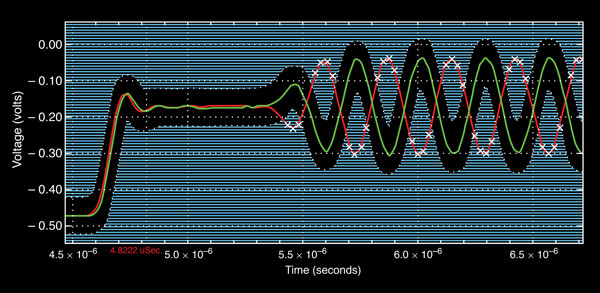

The strength of the system lies in the synchronization and analysis of waveforms using ATTI's patented Automated Waveform Analysis (AWA) tool and its "for test" extension features. The AWA is a key part in a suite of game changing software which fully characterizes mixed signal data from UUTs/DUTs.

The ability to automate the characterization of UUTs/DUTs will significantly reduce costly reverse engineering, specifically when little or no documentation is available. Using the tool set, the test engineer can characterize "known good" assemblies and populate fault libraries using their test engineering skill set knowing where and how to insert detectable faults.

PADS can be deployed as a supplemental maintenance tool or an ideal new technology replacement for obsolete general purpose or dedicated test systems. The footprint and rugged packaging of PADS allows for unprecedented sustainment flexibility.

The software suite keeps accurate and editable details of the test engineer’s test setups and sequences. Using exportable text, application program interface (API) based code is generated by the system's GUI panels. The ACG engine continuously documents macro functionality of the GUI panels for the user. This can be used to support user tasks such as configuration management and revision tracking controls.

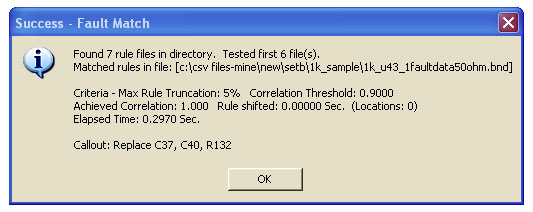

During production testing, test waveforms captured during TPS execution are aligned and verified against signal models. If the verification fails, the fault signature library is automatically evaluated against the current waveform. The faulty component(s) are identified to the operator through a GUI panel.

PADS can be used to produce a cost-effective solution for:

- Systems with limited data available allowing you to build “useable” TPS

- Newly unsupported or homeless UUTs due to:

- Extended life cycles where no support was planned

- Products outliving the repair support in place

General purpose testers commonly use large patch panel interfaces. While well suited for testing a multitude of assemblies, they are not desirable for small scale UUTs/DUTs. Particularly when evaluating interface test adapter (ITA) fixturing, complexity, size or cost. The PADS mechanical engineering advances are significant cost, time and space savers for users when contrasted to common patch panel interfaces or ITAs. The PADS fixturing is more appropriately sized for these types of UUTs/DUTs resulting in simpler, more cost effective ITAs. PADS ITAs are most often a single printed circuit board (PCB), Printed Wire Assembly (PWA) or just a single cable. PADS mechanical advances also include an adjustable circuit card assembly (CCA) holding fixture when desired.